Boiler for Feed Mill: Reliable Steam Solutions for Modern Feed Production

A boiler for feed mill plays a critical role in modern animal feed manufacturing, as steam is an indispensable energy medium throughout multiple processing stages. In feed mills producing poultry, livestock, and aquatic feed, steam is widely used in conditioning, pelleting, extrusion, drying, and sanitation processes. These operations require not only sufficient steam output, but also stable pressure, consistent temperature, and reliable long-term operation. As feed production scales up and energy costs continue to rise, the selection of an appropriate boiler for feed mill has become a strategic decision directly affecting production efficiency, product quality, and operating cost control.

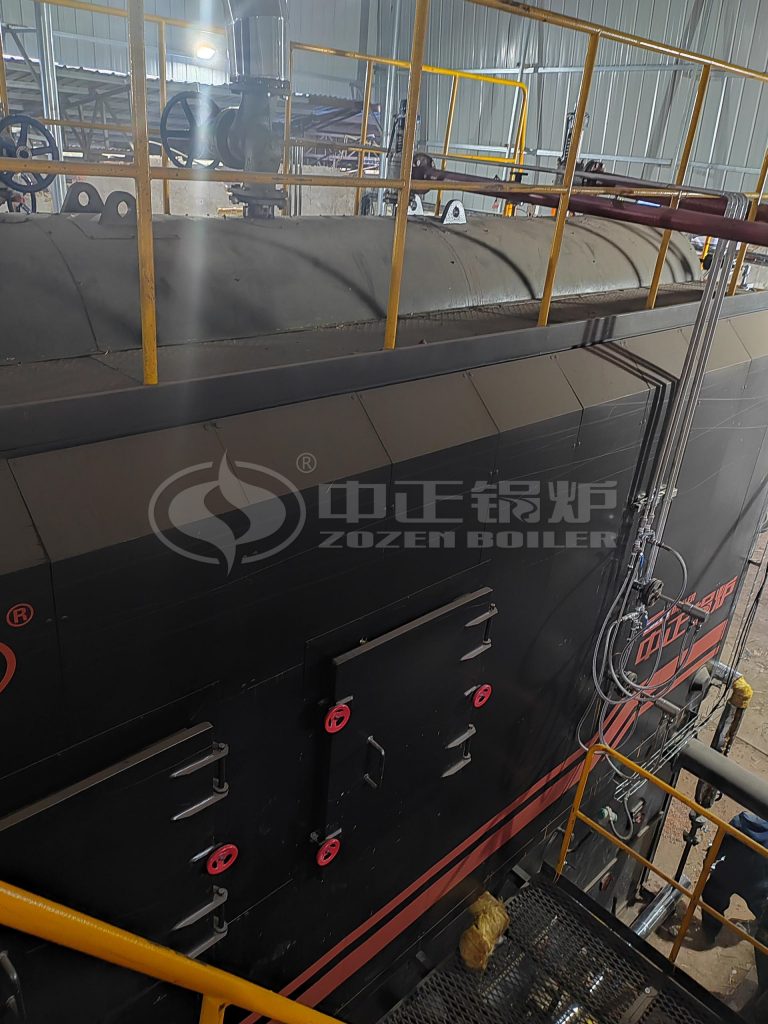

As a professional industrial boiler manufacturer with extensive experience in biomass and solid-fuel boilers, ZOZEN BOILER has developed a range of steam boiler solutions specifically suited for feed mill applications. By combining proven boiler structures, optimized combustion systems, and flexible fuel adaptability, ZOZEN provides reliable boiler for feed mill systems that support stable production while addressing cost and sustainability requirements.

ZOZEN Biomass Steam Boilers for Feed Mill Applications

The SZL biomass steam boiler adopts a horizontal double-drum water-tube structure with a longitudinal arrangement, which allows for a larger furnace volume and sufficient heating surface. This structure is particularly suitable for feed mills with continuous and high-load steam demand. The water-tube design enhances heat transfer efficiency and improves circulation stability, ensuring that the boiler can maintain steady steam pressure even during prolonged operation. For a boiler for feed mill, this stability is essential to avoid process interruptions during conditioning and extrusion.

In terms of combustion, the SZL biomass boiler is equipped with a chain grate system designed to handle a wide range of biomass fuels commonly available near feed production sites. The air distribution system is carefully arranged to support staged combustion, allowing fuel to burn evenly across the grate surface. This design helps maintain consistent furnace temperature, reduces unburned fuel losses, and improves overall thermal efficiency. For feed mills aiming to control energy costs, this feature significantly enhances the economic performance of a boiler for feed mill.

The SZL series also places strong emphasis on operational reliability and environmental compliance. Its furnace and convection heating surfaces are arranged to reduce ash accumulation and facilitate long-term continuous operation. Combined with appropriate dust removal equipment, the boiler can meet local emission requirements while maintaining stable performance. These characteristics make the SZL biomass boiler a dependable boiler for feed mill in regions where sustainability and emission control are increasingly important.

The DZL three-drum biomass steam boiler represents another practical option for feed mills seeking compact layout and efficient operation. This boiler features a three-drum water-fire tube structure that integrates the furnace and heating surfaces into a compact configuration. Despite its relatively small footprint, the DZL biomass boiler provides sufficient heating surface area to ensure stable steam generation under variable loads, making it suitable for feed mills with limited installation space.

ZOZEN BOILER applies strict manufacturing standards to both SZL and DZL biomass steam boilers. A high proportion of CNC machining ensures dimensional accuracy of pressure parts, while standardized welding procedures enhance structural integrity. These manufacturing practices contribute to stable operation and extended service life, which are essential qualities for any boiler for feed mill operating under continuous production conditions.

Case Study: Biomass Boiler for Feed Mill Production Line

In the feed industry, steam quality and supply stability are decisive factors for production efficiency. During conditioning, extrusion, and drying processes, steam must be delivered at stable pressure and temperature to ensure proper feed texture, moisture distribution, and nutritional consistency. Many feed mills also face rising energy costs and increasing environmental requirements, which further complicate boiler selection.

In this project, the customer required a boiler for feed mill capable of supporting conditioning, expansion, and drying processes without interruption. The production line demanded continuous steam supply with minimal pressure fluctuation to prevent variations in pellet quality. At the same time, the customer aimed to reduce operating costs by utilizing locally available biomass fuel while aligning with low-carbon development policies.

To address these requirements, ZOZEN BOILER configured an SZL series biomass chain grate water-tube boiler with a rated capacity of 4 tons per hour. The boiler adopts a horizontal double-drum, longitudinal arrangement that provides sufficient furnace volume and stable water circulation. After commissioning, the boiler demonstrated stable steam pressure with minimal fluctuation, ensuring uninterrupted operation across key feed processing stages.

Under local biomass fuel conditions, the boiler achieved the expected thermal efficiency target, contributing to a noticeable reduction in unit steam cost compared with the previous system. The optimized combustion system ensured steady heat release, while the robust boiler structure supported long-term continuous operation. This performance validated the suitability of the SZL biomass boiler as a reliable boiler for feed mill under demanding industrial conditions.

Throughout the project, ZOZEN BOILER focused on aligning boiler performance with actual production requirements rather than theoretical parameters. By doing so, the boiler system integrated smoothly into the feed mill’s existing process layout and supported stable, efficient operation without introducing unnecessary complexity or maintenance burden.

Why Choose ZOZEN Boiler for Feed Mill Applications

Selecting a boiler for feed mill is not simply about matching steam capacity; it requires a comprehensive evaluation of fuel adaptability, operational stability, manufacturing quality, and long-term service support. ZOZEN BOILER has accumulated extensive experience in providing biomass steam boiler solutions for feed mills across different regions, allowing it to respond effectively to diverse operating conditions.

From technical design to project execution, ZOZEN BOILER focuses on delivering practical and dependable boiler for feed mill solutions. By balancing efficiency, stability, and environmental performance, ZOZEN helps feed producers build energy systems that support consistent product quality and long-term operational efficiency.

In today’s competitive feed industry, a well-designed boiler for feed mill is a foundational asset rather than a supporting accessory. With proven biomass steam boiler technologies and a deep understanding of feed production requirements, ZOZEN BOILER remains a reliable partner for feed mills seeking stable steam supply, controlled energy costs, and sustainable development paths.

LEAVE A MESSAGE

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.